The HMCS Windsor, a Victoria-class submarine used for long-range patrols, came back to Halifax on June 20, 2018. (Photo by Andrew Vaughan, THE CANADIAN PRESS)

Dalhousie University in Halifax is teaming up with Canada’s Department of National Defence to help keep the country’s naval fleet running longer. Their secret weapon? Advanced 3D printing technology that creates replacement parts for ships and submarines, cutting down time and cost dramatically.

Normally, getting a new part for a naval vessel can be expensive and take months. But Paul Bishop, a materials engineer leading the project at Dalhousie, says 3D printing changes the game. “Once we figure out the process, we can print parts in hours or days instead of waiting months,” he explains.

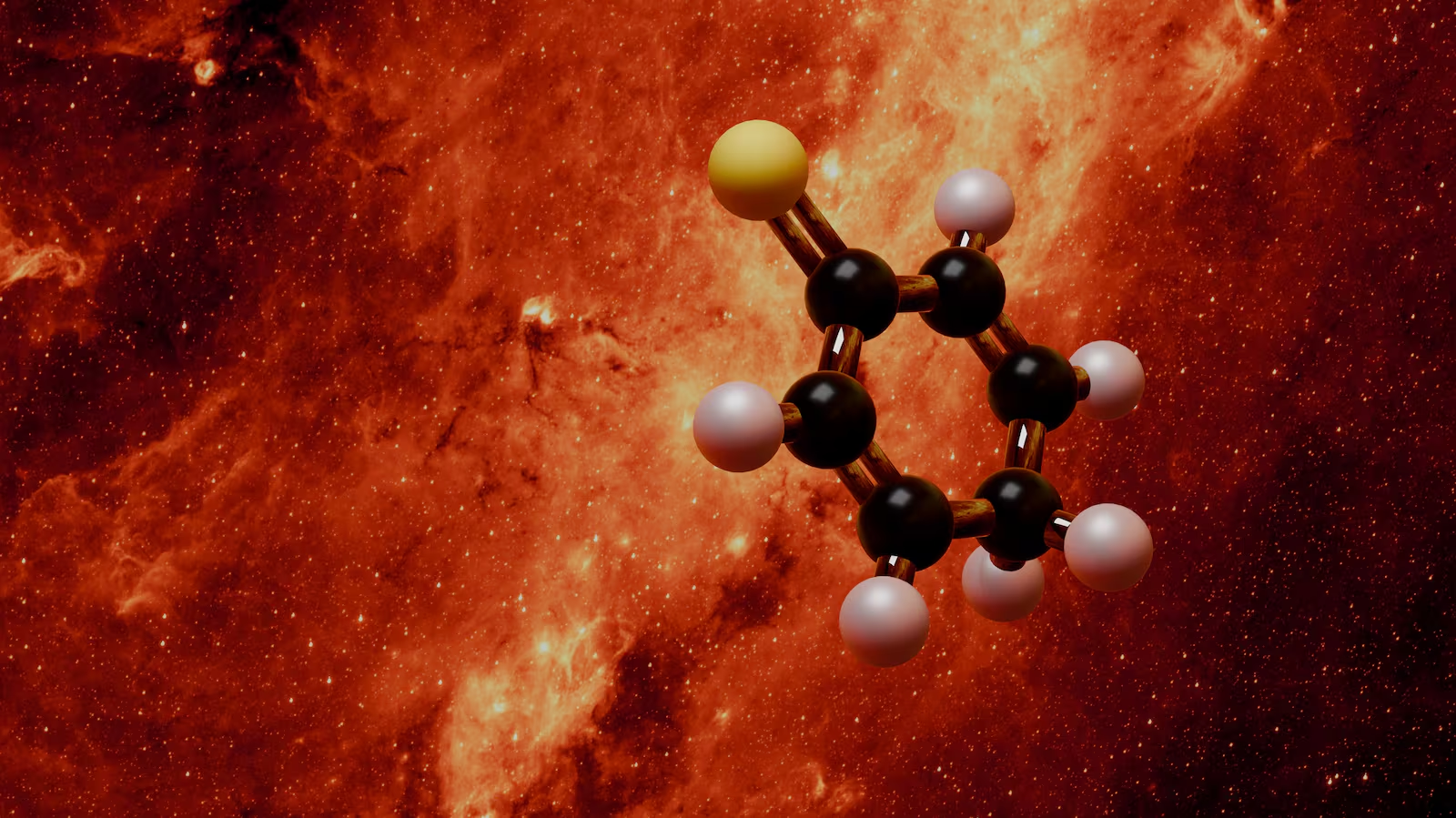

The team starts by turning old metal parts from retired Navy ships into a fine powder. This powder, made mainly of a copper alloy, becomes the raw material for printing new components. This recycling step not only saves resources but also keeps the work within Canada.

Using high-tech machines at Dalhousie’s Advanced Manufacturing Hub, the researchers print parts with incredible detail. They use several 3D printing methods, including one called directed energy deposition. This technique is especially useful for fixing worn or broken parts quickly, allowing ships to return to service much faster and for less money.

The project also involves designing new pieces, like impellers, from the recycled metal powder. Additionally, the technology can repair existing parts by adding layers of material with special properties—such as better resistance to corrosion. This means damaged pipes or other components can be rebuilt and used again, extending their life.

One key advantage Bishop points out is that all this work happens right here in Canada. “We want to keep everything secure and build a strong defence industry locally,” he says. The hope is that many Canadian companies will join this effort to support the navy with these advanced repair and manufacturing techniques.

This partnership has been a win for everyone involved. With the university close to Canada’s naval base, the collaboration strengthens ties between education, technology, and the armed forces. Dalhousie’s 3D printing project offers a smarter, faster, and more cost-effective way to maintain the country’s naval fleet, ensuring ships stay ready for duty without long waits or huge expenses.